Info

Kept to what really matters

The HL 25-12 LEANbasic achieves the fastest possible cycle times and top productivity thanks to astonishingly short non-productive times with traditional positively controlled Pfiffner hydraulic valves. Similarly to a cam-controlled machine, the HL 25-12 produces simple precision parts with a diameter of up to 25 mm in just seconds. Its cost-effectiveness is second to none. The HL 25-12 is the ideal entry-level machine, not least due to the intuitive PLC control and the tried-and-tested, reasonably priced LEAN units.

More opportunities with CNC, the newly launched HLC 25-12 LEANhybrid combines the unrivaled productivity of hydraulic positively controlled rotary transfer machines with the CNC technology that is indispensable for complex machining processes. The Bosch MTX control forms the basis for up to 12 optional CNC axes (max. 4 CNC stations). The latest digital drive technology with SERCOS III bus connects the axis control valves and variable-speed spindle drives with the Bosch MTX. Possible applications with the CNC options: Contour turning, contour milling, clamping compensation, 4-axis interpolation etc.

The Hydromat LEANbasic and LEANhybrid series are also available for 32 and 45 mm diameters.

Workpieces

Top precision at the perfect price

With the Pfiffner Hydromat® LEAN rotary transfer machine, you can produce the following workpieces cost-effectively:

Anchor

Material

Steel

Area

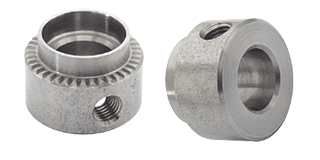

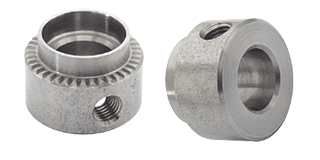

Clamping ring

Material

Steel

Area

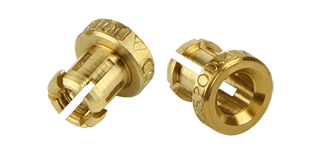

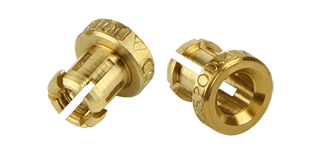

Clamping sleeve

Material

Brass

Area

Plug, throttle body, shut-off body

Material

Brass

Area

Housing

Material

Aluminum

Area

- - -

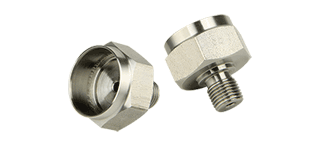

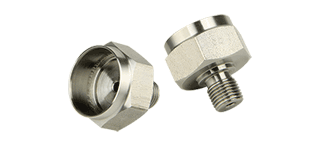

Head nut

Material

Alloy, Nickel-chromium-iron alloy

Area

Contact strip

Material

Copper

Area

- - -

Anchor

Material

Steel

Area

Clamping ring

Material

Steel

Area

Clamping sleeve

Material

Brass

Area

Plug, throttle body, shut-off body

Material

Brass

Area

Housing

Material

Aluminum

Area

- - -

Head nut

Material

Alloy, Nickel-chromium-iron alloy

Area

Contact strip

Material

Copper

Area

- - -