Info

Machining complex turned and milled parts

No-compromise machining of even high-strength materials in the turning, milling, and drilling areas. With top precision and process reliability for mass production. Thanks to these exceptional properties, the Pfiffner RT 100 -12 CNC really stands out.

12 independently driven workpiece spindles and up to 18 machining modules arranged horizontally and vertically enable the most challenging of 6-side machining tasks. Machining can take place from the bar or from blanks.

During the processing of blanks, as well as the workpieces being loaded they are measured in their clamping position and then corrected accordingly at subsequent machining stations. This means that any dimensional variations on the blanks themselves are detected and compensated for. The high modularity of the RT 100 -12 means that there are practically endless configuration possibilities for the optimum, most cost-effective production of workpieces.

| More power | Pfiffner RT 100 rotary transfer machines are rotary indexing tables with 12 independently driven workpiece spindles and up to 18 removable, simultaneously working machining modules arranged horizontally and vertically. They can master the most challenging of tasks in the 6-side machining of highly complex mass-produced parts at the highest quality level. |

|---|---|

| Top flexibility | Thanks to the Bosch MTX control, Pfiffner RT 100 rotary transfer machines can master up to 99 axes and 25 NC channels at the same time. They enable workpieces to be loaded and unloaded in parallel with the cycle time and can be optimized for the needs of the individual customer. Thanks to the standard units and use of turrets, our machines can process really complex workpieces but also a wide variety of workpieces. |

| Top cost-effectiveness | Pfiffner RT 100 rotary transfer machines are always built upon the same basic module with up to 18 insertable machining modules (12 horizontal and 6 vertical). The flexible structure of the machining modules for all of the stations can be reconfigured at any time to provide almost endless configuration possibilities. Thanks to reliable in-process measurements, top dimensional accuracy can be achieved. |

|---|---|

| All machining types | Pfiffner RT 100 rotary transfer machines are suitable for turning, milling, drilling, dovetailing, broaching, wobble broaching, honing, grinding, and assembling. In cases where challenging workpieces need to be produced in large quantities and with high precision, Pfiffner rotary transfer machines offer the best solution. |

Workpieces

Top precision at the perfect price

With the Pfiffner RT rotary transfer machine, you can produce the following workpieces cost-effectively:

Input shaft, shaft

Material

Steel

Area

Injector body

Material

Steel

Area

Cylinder core, rotor

Material

Brass

Area

Cylinder head

Material

Steel

Area

- - -

Cylinder block

Material

Steel

Area

CP4 cylinder head

Material

Steel

Area

Guide bush

Material

Steel

Area

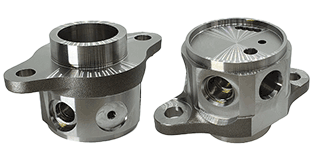

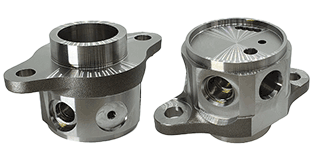

Pump body

Material

Stainless steel

Area

Input shaft, shaft

Material

Steel

Area

Injector body

Material

Steel

Area

Cylinder core, rotor

Material

Brass

Area

Cylinder head

Material

Steel

Area

- - -

Cylinder block

Material

Steel

Area

CP4 cylinder head

Material

Steel

Area

Guide bush

Material

Steel

Area

Pump body

Material

Stainless steel

Area