Info

Top productivity for a reduction in costs per part

Witzig & Frank Turmat rotary transfer machines offer four to twelve stations and up to 33 machining units that work in parallel to provide 3/5-side machining with an optional B axis. The processes include drilling, milling, threading, honing, grinding, turning, broaching, forming, annealing, measuring, inspecting, and assembling. The suspended rotary transfer unit ensures free chip fall and high process reliability.

| More power | Witzig & Frank Turmat rotary transfer machines offer 4-12 stations for the machining of rotationally symmetrical workpieces up to max. D x L 250 x 350 or, for cubic workpieces, WxHxL 250 x 250 x 350. Other dimensions are possible after testing. |

|---|---|

| Top flexibility | Witzig & Frank Turmat rotary transfer machines can be modularly adjusted to meet individual requirements. This is done, for example, using pick-up turning units, tool changers, face turning heads, or a central coolant supply. |

| Top cost-effectiveness | Witzig & Frank Turmat rotary transfer machines enable 3/5-side machining with an optional B axis as well as loading/unloading in parallel with the cycle time. This allows even large production orders to be realized with the shortest cycle times and top precision. |

|---|---|

| All machining types | Witzig & Frank Turmat rotary transfer machines offer all technologies required for the precise machining of workpieces: Drilling, milling, threading, honing, grinding, turning, broaching, forming, annealing, measuring, inspecting, and assembling. |

Workpieces

Top precision at the perfect price

With the Witzig & Frank Turmat rotary transfer machine, you can produce the following workpieces cost-effectively:

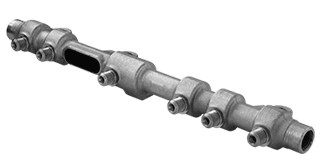

High-pressure rails

Material

Steel/casting

Area

High-pressure rails

Material

Steel/casting

Area

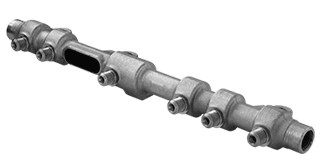

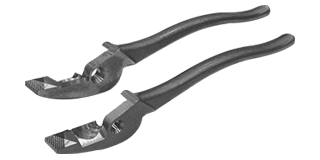

Pliers

Material

Steel

Area

Material handling technology chain link

Material

Steel

Area

Construction machine chain link

Material

Steel

Area

Rocker arm (car)

Material

Steel

Area

Rocker arm (truck)

Material

Steel

Area

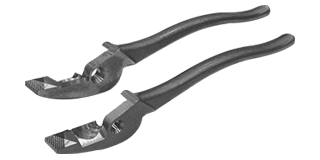

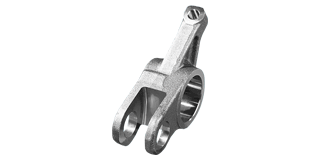

Steering fork

Material

Steel

Area

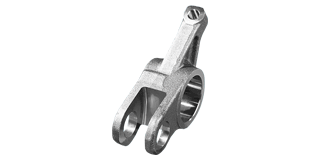

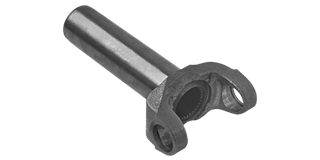

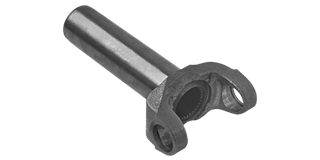

Yoke

Material

Steel

Area

Crossbar

Material

Steel

Area

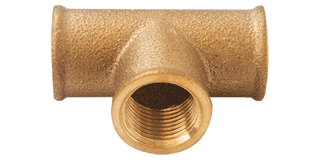

Fittings

Material

Brass

Area

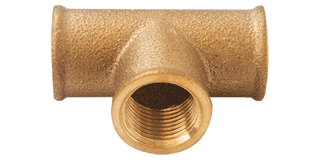

Fitting

Material

Brass

Area

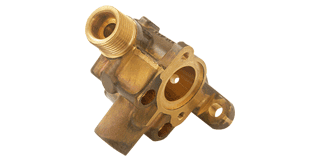

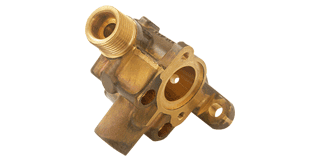

Gas valve

Material

Brass

Area

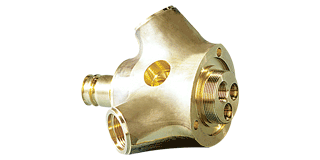

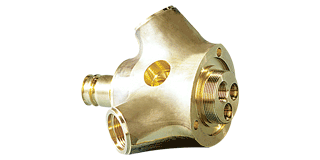

Distributor

Material

Brass

Area

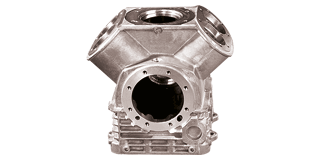

Compressor housing

Material

Casting

Area

Washing machine bearing element

Material

Casting

Area

Door check

Material

Casting

Area

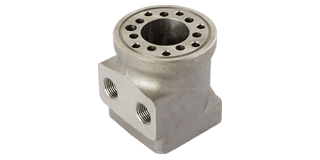

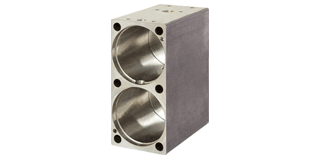

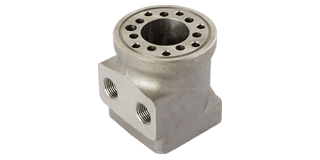

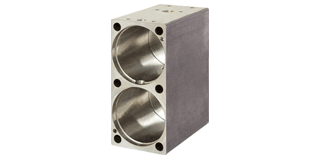

Hydraulic housing

Material

Casting

Area

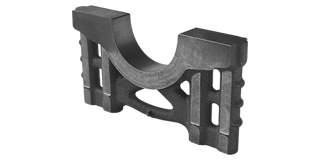

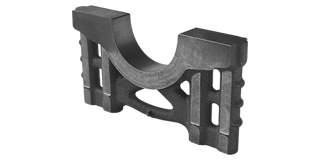

Crankshaft bearing cap

Material

Casting

Area

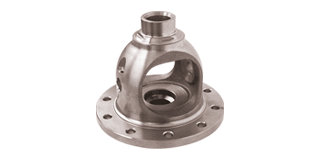

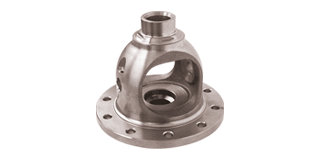

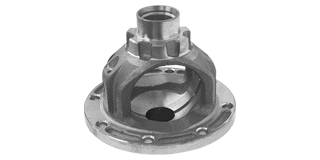

Differential housing, calotte design

Material

Casting

Area

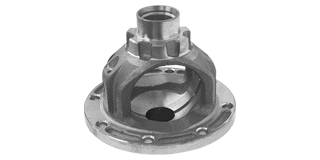

Differential housing, sphere design

Material

Casting

Area

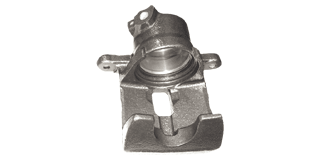

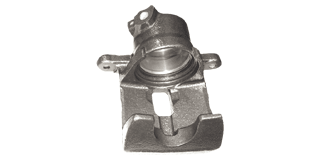

Brake body

Material

Casting

Area

Hydraulic valves

Material

Stainless steel/steel/copper

Area

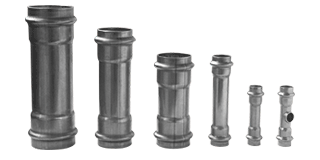

Bent press fitting

Material

Stainless steel/steel/copper

Area

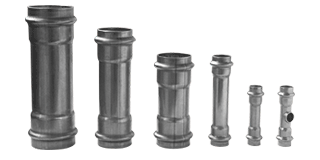

Straight press fitting

Material

Stainless steel/steel/copper

Area

Planetary carrier

Material

Aluminum

Area

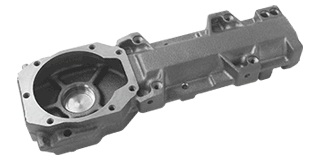

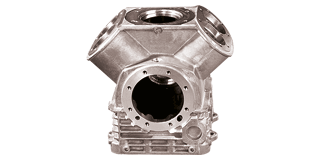

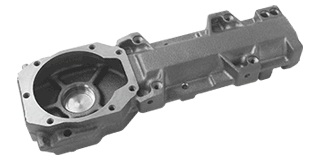

Steering box

Material

Aluminum/casting

Area

Pliers

Material

Steel

Area

Material handling technology chain link

Material

Steel

Area

Construction machine chain link

Material

Steel

Area

Rocker arm (car)

Material

Steel

Area

Rocker arm (truck)

Material

Steel

Area

Steering fork

Material

Steel

Area

Yoke

Material

Steel

Area

Crossbar

Material

Steel

Area

Fittings

Material

Brass

Area

Fitting

Material

Brass

Area

Gas valve

Material

Brass

Area

Distributor

Material

Brass

Area

Compressor housing

Material

Casting

Area

Washing machine bearing element

Material

Casting

Area

Door check

Material

Casting

Area

Hydraulic housing

Material

Casting

Area

Crankshaft bearing cap

Material

Casting

Area

Differential housing, calotte design

Material

Casting

Area

Differential housing, sphere design

Material

Casting

Area

Brake body

Material

Casting

Area

Hydraulic valves

Material

Stainless steel/steel/copper

Area

Bent press fitting

Material

Stainless steel/steel/copper

Area

Straight press fitting

Material

Stainless steel/steel/copper

Area

Planetary carrier

Material

Aluminum

Area

Steering box

Material

Aluminum/casting

Area